Bowtie Analysis is a risk management approach that focuses on identifying hazards, evaluating associated risks, and creating a visual representation to map out preventive and mitigative controls. The name comes from the diagram’s shape, which looks similar to a bowtie. This approach is especially valuable in high-risk industries such as aviation, oil and gas, healthcare, and others for managing safety and operational risks.

Ensuring safe industrial operations remains a top priority in Malaysia, particularly for sectors with elevated risks such as oil and gas, petrochemicals, chemical manufacturing, energy production, and heavy industry. As Malaysia continues its push toward industrial growth, it faces increasing scrutiny from both local regulatory bodies and global partners regarding safety and risk management practices.

Within this context, Bowtie Analysis has become a central tool in the risk management toolkit of many Malaysian organizations. It offers a balanced blend of visual simplicity and analytical depth, which is pivotal for communicating complex safety concepts to diverse teams, from shop-floor operators up to senior management. Bowtie Analysis stands out not only for mapping accident scenarios but also for demystifying how organizational controls work or fail across the full life cycle of hazardous processes.

This expansive review explores the background, methods, implementation, and evolving applications of Bowtie Analysis within Malaysia’s regulatory and industrial landscape. Drawing on international best practices and the Malaysian regulatory context, this article provides practical guidance for organizations contemplating or refining their use of Bowtie Analysis for process safety.

Ready to Strengthen Your Process Safety Strategy?

Learn how Bowtie Analysis can transform your approach to managing operational risks in Malaysia’s high-risk industries.

- What Are the Key Methods Used in Bowtie Analysis for Risk Management?

- How Is Bowtie Analysis Applied Across Malaysian Industries?

- How Does Bowtie Analysis Align with Malaysian Regulatory Requirements?

- What Are the Challenges and Opportunities in Integrating Bowtie Analysis into Operations?

- How Wellkinetics Can Help

What Are the Key Methods Used in Bowtie Analysis for Risk Management?

Bowtie Analysis methods help organizations systematically identify hazards, assess risks, and visualize the links between causes, controls, and consequences. This approach supports clear communication and effective management of process safety risks.

What Is Bowtie Analysis and How Did It Evolve into a Risk Management Tool?

Bowtie Analysis derives its name from the distinctive diagram that lies at its core. Although the technique gained widespread adoption in the late 20th century, its conceptual roots go back to risk mapping principles developed in high-hazard industries such as aviation and oil & gas. Today, organizations globally rely on Bowtie Analysis for risk assessments related to health, safety, environment, and business continuity.

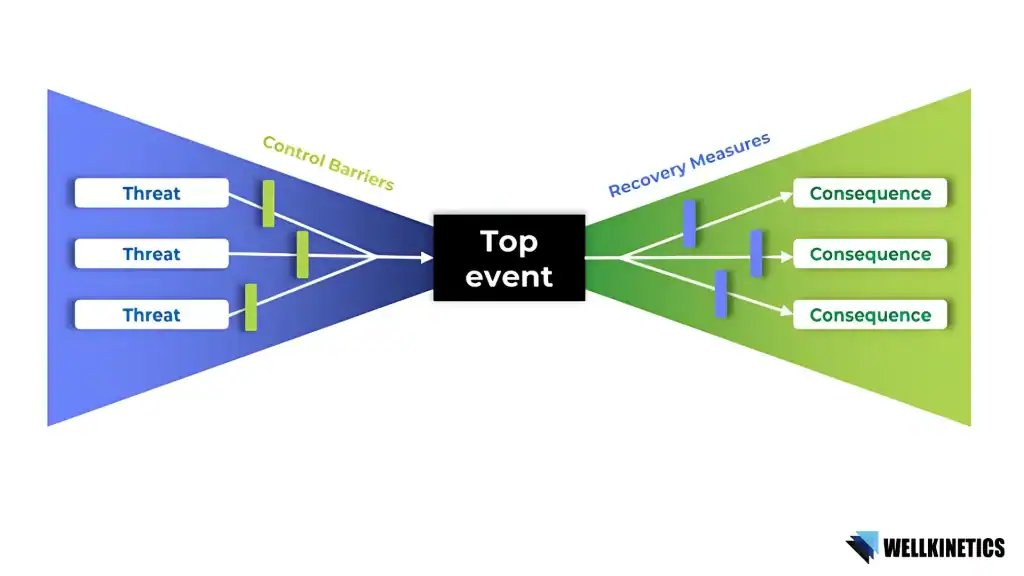

At its essence, Bowtie Analysis provides a framework for organizations to visualize the pathways from hazard to potential loss, and to map out the critical controls known as “barriers” that interrupt or mitigate these pathways. Unlike linear risk assessment methods, the bowtie diagram’s dual-sided structure simultaneously addresses both the causes (threats/initiating events) and the effects (consequences/impacts) of a top event. This parallel focus is invaluable for industries confronting a spectrum of possible operational upsets.

What Are the Key Components of a Bowtie Diagram and How Do They Work Together?

The bowtie diagram is built around several foundational components:

- Hazard: The inherent source of risk with the potential to cause harm—such as flammable chemicals, high-pressure systems, or hazardous waste materials.

- Top Event: The central incident that represents the “loss of control” moment, e.g., a chemical release, fire outbreak, or equipment rupture. This forms the heart of the diagram and is the pivot between threat and consequence.

- Threats: Situations or occurrences that have the potential to directly cause the top event. Examples include equipment failure, operator error, or natural hazards like lightning or floods.

- Consequences: The undesirable outcomes if the top event occurs, often including injuries, loss of containment, environmental contamination, asset damage, or reputational harm.

- Barriers: Measures that prevent threats from causing the top event (preventive) or that mitigate the consequences once a top event occurs (mitigative). Barriers can be engineered controls (valves, alarms), procedural (training, SOPs), or organizational (oversight, culture).

A fully developed bowtie diagram is not only a technical artifact but a powerful communication tool, facilitating operational awareness at every organizational level.

What Are the Core Steps in Conducting a Bowtie Analysis Effectively?

To ensure systematic implementation and effectiveness, Bowtie Analysis typically proceeds through the following structured phases:

1. Hazard Identification

The first step involves using techniques like HAZOP (Hazard and Operability Study), FMEA (Failure Modes and Effects Analysis), and methods for qualitative risk prioritization. International standards like ISO 31000 and Malaysian frameworks (e.g., HIRARC—Hazard Identification, Risk Assessment, Risk Control) guide this phase.

2. Top Event Definition

Subject matter experts define the “loss of control” incident most relevant to their process. Precise language is critical: too broad a definition hinders actionable control mapping, too narrow limits the scope.

3. Threat and Consequence Mapping

Teams brainstorm all plausible threats and consequences related to the top event, engaging cross-disciplinary expertise (operations, maintenance, health & safety, etc.). This collaborative approach ensures comprehensiveness and buy-in.

4. Barrier Identification and Evaluation

Each barrier is explicitly described, assessed for its independence (avoidance of common-cause failures), and evaluated for its effectiveness. Methods like Layer of Protection Analysis (LOPA) are often used for quantitative assessment.

5. Diagram Construction

Whether via specialized Bowtie software or using manual templates, the data is organized into the bowtie’s visual structure, fostering clear understanding and engagement.

6. Validation and Communication

The draft diagram is rigorously reviewed often in facilitated workshops. The goal is consensus validation and operational ownership.

7. Barrier Management & Monitoring

Bowtie Analysis, done well, does not end with the diagram. Organizations must monitor barriers over time, assign responsibilities for barrier integrity, and regularly audit for drift or degradation.

Need Help Implementing Bowtie Step-by-Step?

Wellkinetics guides you through every stage of the Bowtie Analysis process from hazard identification to barrier monitoring.

What Are the Best Practices for Conducting an Effective Bowtie Analysis?

Best practices for Bowtie Analysis promote clarity, integration, and continuous improvement by engaging stakeholders, using accessible language, and ensuring alignment with organizational systems.

- Engagement: Success hinges on engaging staff who operate, maintain, and supervise the process, not solely risk specialists.

- Clarity: Diagrams must use clear, jargon-free language for universal comprehension.

- Integration: Bowtie Analysis should tie into existing safety, training, and maintenance systems; no process exists in isolation.

- Continuous Improvement: Bowtie diagrams should be living documents, updated after audits, incidents, or process changes.

How Is Bowtie Analysis Applied in the Malaysian Industrial Context?

While the core technique is universal, applying Bowtie Analysis in the Malaysian context reveals certain distinctive features and challenges:

- Workforce Diversity: Malaysia’s manufacturing and process industries employ a multicultural, multilingual workforce. This increases the necessity for diagrams and barriers to be accessible, sometimes requiring translation or pictorial representations to ensure full comprehension.

- Regulatory Integration: In Malaysia, successful analyses are often cross-referenced with local requirements (e.g., Factories and Machinery Act, OSHA 1994). Alignment with these regulations (and with client requirements for multinational operators) enhances both compliance and operational relevance.

How Is Bowtie Analysis Applied Across Malaysian Industries?

Bowtie Analysis is increasingly utilized across Malaysian industries to enhance process safety, regulatory compliance, and risk-based decision-making. It supports companies in visualizing complex risk scenarios and ensuring robust barrier management tailored to local operational contexts.

How Is Bowtie Analysis Used in Malaysia’s Oil and Gas Sector?

Malaysia’s oil and gas sector remains one of the region’s largest, contributing around 20% to the nation’s GDP (according to Malaysian Investment Development Authority). The environment is both high-risk and heavily regulated, making effective risk management systems a non-negotiable aspect of operations. Bowtie Analysis saw early adoption in this sector, driven largely by global best practices imported by multinational firms operating within Malaysia.

Key Application Examples

- Offshore Drilling Operations: Bowtie Analysis is routinely applied to critical operations such as blowout prevention. Typical hazards include high-pressure gas pockets and mechanical failure. Preventive barriers might consist of BOP (Blowout Preventer) systems, strict permit-to-work (PTW) protocols, and routine well integrity tests. Mitigative barriers might include remote well shutdown and emergency muster plans.

- Refinery & Downstream Operations: Here, Bowtie Analysis is used to map hazards like hydrocarbon releases or fires. Organizations map out ignition risks (threat) and install fire and gas detection systems (mitigative barrier).

- Pipeline Integrity: Malaysian operators often deploy Bowtie Analysis for long-distance pipelines, focusing on threats such as third-party interference, corrosion, or natural disasters. Preventive barriers could be land patrols, surveillance systems, or advanced SCADA monitoring.

ALSO READ: HAZOP in Oil and Gas Industry: How to Prepare, Conduct, and Improve Safety in Malaysia

Are You in a High-Risk Industry?

Oil & gas, chemicals, or power—whatever your field, our Bowtie solutions are industry-specific and regulator-approved.

How Is Bowtie Analysis Applied in Malaysia’s Manufacturing and Process Industries?

Malaysia’s manufacturing sector is broad, covering electronics, automotive, food processing, and more. Bowtie Analysis here is valued for making safety concepts accessible to operators of varying technical backgrounds. Example use cases include:

- Machine Safety: Hazards include moving parts, high voltages, and hot surfaces. Threats often include improper lockout/tagout (LOTO), operator distraction, or unplanned maintenance.

- Chemical Processing: Applications center on controlling risks during blending, mixing, or transfer of chemicals. Barriers include automatic shut-offs, sequence interlocks, and procedural controls.

How Does Bowtie Analysis Enhance Safety in Chemical Processing and Storage Facilities in Malaysia?

Malaysian chemical producers face substantial risks associated with bulk chemical storage, transfer, and use of reactive materials. Bowtie Analysis supports the sector’s risk compliance by:

- Systematically mapping tank farm hazards, e.g., overfilling, tank rupture, uncontrolled reaction.

- Identifying threats arising from supplier errors, inadequate maintenance, or extreme weather events.

- Prioritizing barriers such as double-walled tanks, dike systems, and predictive analytics for maintenance planning.

How Is Bowtie Analysis Applied in Malaysia’s Energy and Power Generation Sector?

The expansion of Malaysia’s renewable energy sector (solar, wind, and bioenergy) calls for fresh applications of Bowtie Analysis. Hazards in these domains may include electrical faults, fire outbreaks at biomass plants, or blade detachment risks in wind turbines. Preventive barriers are engineered (protective relays, fire suppression), while mitigative barriers include grid isolation protocols or remote shutoffs.

Which Other Malaysian Industries Are Using Bowtie Analysis and Why?

Pharmaceuticals, water treatment, and other industries in Malaysia are beginning to integrate Bowtie Analysis into their safety and compliance processes, benefitting from its clarity and ease of understanding.

- Pharmaceuticals: Used to control risks involving airborne contamination, sterile failures, or solvent fires. Bowtie diagrams support GMP (Good Manufacturing Practice) compliance.

- Water Treatment: Bowtie Analysis is applied to hazards in chemical dosing, disinfection byproducts, or supply interruptions.

ALSO READ: From Hazard to Harmony: Achieving Process Safety in the Pharma Sector

How Does Bowtie Analysis Align with Malaysian Regulatory Requirements?

Malaysia’s regulatory framework promotes systematic risk identification and management. Bowtie Analysis aligns well with compliance requirements under OSHA 1994, CIMAH, and international standards like ISO 45001, enhancing safety and operational practices.

What Are the Key Malaysian Laws Supporting Process Safety and Bowtie Analysis?

Malaysia’s regulatory system sets clear expectations for managing major hazards. Laws and standards directly relevant to Bowtie Analysis include:

- Occupational Safety and Health Act 1994 (OSHA 1994): Applies to nearly all workplaces, placing onus on employers to ensure, so far as practicable, the safety of workers. Section 15 mandates risk management.

- Factories and Machinery Act 1967: Requires compliance with safety prescriptions for machinery and hazardous processes.

- Environmental Quality Act 1974 (EQA 1974): Governs pollution and emission, aligning with process safety for chemical facilities.

- Control of Industrial Major Accident Hazards (CIMAH) Regulations 1996: Adopted from the UK COMAH framework, CIMAH specifically targets establishments where dangerous substances are present in large enough quantities to prompt major accident potential.

- Industry Codes of Practice (ICOP): E.g., ICOP for Safe Working in Confined Spaces (2010).

How Does Bowtie Analysis Help Meet Malaysian Regulatory Expectations?

Bowtie Analysis is recognized by Malaysian regulatory bodies as a robust tool for risk identification, management, and compliance. It supports organizations in meeting local requirements such as HIRARC and CIMAH, while also aligning with international safety standards, providing clear documentation and evidence of effective control systems.

How Does Bowtie Analysis Enhance HIRARC-Based Risk Assessment in Malaysia?

Malaysian authorities require systematic risk identification, assessment, and control. HIRARC is the nationally recognized methodology, and Bowtie Analysis is increasingly regarded as a best-in-class tool for meeting these requirements especially for complex or high-vulnerability processes.

How Does Bowtie Analysis Support Compliance with CIMAH Regulations in Malaysia?

CIMAH entails preparing a written safety report detailing foreseeable major accident scenarios and controls. Bowtie diagrams have become a standard method for documenting and demonstrating these requirements. In fact, enforcement inspections frequently request bowtie outputs as evidence of compliance during plant visits.

How Does Bowtie Analysis Align with International Safety Standards in Malaysia?

Leading Malaysian firms (particularly those with multinational investment) align their safety management systems with global standards such as ISO 45001 (Occupational Health and Safety Management), IEC 61511 (Functional Safety), and API RP 754 (Process Safety Performance Indicators). Bowtie Analysis bridges these international expectations with local regulatory obligations.

What Are the Emerging Regulatory Trends for Bowtie Analysis in Malaysia?

Malaysian regulators have progressively emphasized not just compliance but also the effectiveness of controls. Audits now commonly assess barrier integrity through real-world testing (e.g., activation of emergency systems, competency checks). There is also a regulatory push toward digitalization; authorities encourage real-time monitoring and integration of bowtie management systems into operational control rooms.

Ensure CIMAH and OSHA Compliance with Confidence

We support your regulatory submissions with Bowtie diagrams that meet DOSH and global standards.

What Are the Challenges and Opportunities in Integrating Bowtie Analysis into Operations?

The integration of Bowtie Analysis into operational processes presents both challenges and opportunities for organizations striving to enhance safety and compliance.

What Are the Challenges in Adopting Bowtie Analysis?

Adopting Bowtie Analysis may pose difficulties such as resource constraints, lack of expertise, and resistance to change within organizations.

- Cost and Resource Intensity

- Investment in software, training programs, and facilitation workshops is needed. For SMEs, these upfront costs can be a barrier.

- Continuous maintenance: Bowtie diagrams must be updated regularly to reflect process changes, new threats, or barrier degradation.

- Expertise and Competence

- There is a shortage of Bowtie-trained facilitators and practitioners, creating a reliance on foreign consultants or limited local expertise.

- Knowledge transfer: Effective knowledge transfer to frontline staff (often occurring in multiple languages) is essential but not always well executed.

- Integration with Existing Systems

- Many Malaysian organizations already have multiple risk assessment protocols in place. Integrating Bowtie Analysis with current safety systems (ISO, Lean, Six Sigma) without redundancy can be challenging.

- Avoiding “tick-box” syndrome: Without strong leadership and sustained commitment, Bowtie diagrams risk becoming one-off documents for audits rather than living management tools.

- Cultural and Behavioral Change

- Transitioning to an open, proactive safety culture (as Bowtie Analysis demands) means encouraging open reporting of hazards, near misses, and barrier failures.

- Some operators are wary of the additional workload or fear blame if barriers are found lacking.

Facing Barriers in Barrier Management?

Let Wellkinetics simplify the process with digital tools, training, and expert guidance tailored to your team.

What Are the Opportunities for Expanding Bowtie Analysis?

Expanding the use of Bowtie Analysis can enhance operational safety by identifying risks in new areas and improving collective awareness of potential failures.

- Digital Transformation and Data Integration

- Adoption of digital bowtie management platforms enables real-time barrier monitoring, automated reporting, and integration with maintenance systems (SAP, Maximo).

- Predictive analytics: Combining Bowtie Analysis with sensor data and AI for early warning of barrier degradation.

- Regulatory Alignment: From Compliance to Value Creation

- Proactive Bowtie Analysis enhances not just compliance but value creation by reducing downtime, insurance premiums, and reputational risks.

- Firms recognized for outstanding risk management, such as those winning national safety awards, increasingly showcase Bowtie Analysis as a differentiator.

- Workforce Empowerment and Safety Culture

- Bowtie Analysis enables practical workforce engagement through visual tools, scenario walkthroughs, and hazard hunts. Involving staff in diagram creation yields deeper awareness and ownership.

- Professional associations (e.g., Malaysian Society for Occupational Safety & Health) support Bowtie Analysis training and certification, building knowledge and competence nationwide.

- Cross-Sector Applicability

- As new industries (biotechnology, renewable energy, advanced electronics) emerge, Bowtie Analysis offers a scalable, adaptable method for novel risk scenarios.

What Are the Recommendations for Effective Bowtie Implementation?

To effectively implement Bowtie Analysis, organizations should adopt a structured approach tailored to their specific needs while fostering collaboration across all involved parties. Below are key recommendations to maximize success and drive value from the process.

- Tailored Training: Invest in facilitator and operator-level courses, with materials adapted linguistically and culturally.

- Leadership Commitment: Senior management should visibly champion Bowtie Analysis.

- Integrated Auditing: Link bowtie diagrams directly to incident investigations and maintenance planning.

- Barrier Ownership: Assign clear responsibilities for barrier inspection and testing; use digital systems to track performance.

How Wellkinetics Can Help

Wellkinetics offers comprehensive support for organizations seeking to implement and optimize Bowtie Analysis in Malaysia. Our services are designed to address both regulatory requirements and industry best practices:

- Tailored Training Programs: We deliver customized training to ensure your team fully understands the Bowtie methodology, regulatory expectations, and practical application specific to your processes.

- Barrier Management Support: We provide ongoing assistance with barrier performance monitoring, regular compliance updates, and seamless integration into your existing safety management systems.

- Expert Consultation: Our team of experienced consultants works alongside your organization to guide you through every phase (from initial assessment to continuous improvement) ensuring the Bowtie methodology delivers real risk reduction and resilience.

By partnering with Wellkinetics, you can improve risk awareness, strengthen operational safety, and keep pace with evolving industry standards in Malaysia.

Learn more about our process safety management consulting services.

References and Further Reading

- Department of Occupational Safety and Health Malaysia (DOSH) Official Guidelines

- Control of Industrial Major Accident Hazards (CIMAH) Regulations 1996

- Occupational Safety and Health Act 1994 (Act 514)

- ISO 31000 Risk Management Standard (2023 update)