HAZOP Analysis which stands for Hazard and Operability Analysis, is a systematic process that helps identify and mitigate risks within various sectors. It goes beyond traditional risk assessment by examining potential hazards and their impact on specific operations. This article will dive into the importance of Hazard and Operability analysis in ensuring safety, exploring its purpose, study process, tools, and templates for effective implementation.

By understanding Hazard and Operability analysis, you will gain valuable insights into how industries effectively manage risks, promoting a safer and well-protected environment. So, let’s dive into the world of HAZOP and uncover the keys to ensuring safety across different sectors.

What is HAZOP?

HAZOP, also known as Hazard and Operability Analysis or HAZOP Study, is a systematic and structured approach used to identify and assess potential hazards and risks associated with complex industrial processes. Its primary purpose is to ensure the safety and operational integrity of such processes across various industries.

The Hazard and Operability analysis process involves assembling a multidisciplinary team consisting of experts from different fields, including engineers, operators, and safety professionals. Together, they conduct a HAZOP workshop, systematically analyzing each step, node, and deviation from normal operating conditions. By utilizing suitable guidewords, the team identifies possible hazards and operability issues, enabling proactive risk management and helping to prevent accidents and near-misses.

Hazard and Operability (HAZOP) analysis is especially vital in high-risk sectors such as manufacturing and pharmaceuticals, where complex processes are prevalent. By thoroughly examining the process, equipment, and human performance, the HAZOP methodology ensures early hazard identification and control, minimizing the likelihood of incidents and enhancing overall safety across operations.

Want to Implement HAZOP Analysis?

Wellkinetics can guide you through the HAZOP process to improve your safety protocols.

Understanding the HAZOP Process

Conducting a Hazard and Operability (HAZOP) analysis is a structured and systematic approach to identify potential hazards or operational problems within a process system. The process involves assembling a team of experts, defining parameters, and thoroughly examining nodes of the system to uncover potential risks. Here is a step-by-step breakdown of the Hazard and Operability process:

1. Building a HAZOP Team

The first step in conducting a Hazard and Operability analysis is to establish a multidisciplinary team consisting of individuals with different areas of expertise. This team typically includes process engineers, operators, maintenance personnel, and safety experts. Their collective knowledge and experience will help in comprehensively analyzing the system.

2. Identifying Processes and Nodes

Next, the team identifies the processes and nodes that will be evaluated during the Hazard and Operability analysis. Processes are the individual steps or actions within the system, while nodes represent the different points or components where potential hazards can manifest.

3. Defining Parameters

For each process and node identified, the team systematically examines relevant parameters such as temperature, pressure, flow rate, and composition. By considering deviations from expected values, they can identify potential risks or hazards associated with each parameter.

4. Establishing Safety Monitoring

During the analysis, the team identifies appropriate safety measures and monitoring systems to ensure early detection and prevention of potential hazards. This may include implementing safety interlocks, alarms, or other control mechanisms to mitigate risks.

By following these steps, a HAZOP analysis provides valuable insights into the potential risks within a process system. It enables organizations to proactively address and mitigate these risks, ultimately enhancing safety and preventing potential accidents or incidents.

Remember, accurate and thorough documentation throughout the Hazard and Operability process is essential. This documentation serves as a valuable reference for future evaluations and ensures consistent application of safety measures.

Importance of HAZOP Analysis in Different Industries

HAZOP analysis plays a critical role in various industries, ensuring safety and minimizing risks associated with complex processes. This systematic assessment tool is essential for identifying potential hazards and implementing effective risk management practices. Let’s explore the significance of the Hazard and Operability methodology in sectors such as manufacturing, oil and gas, pharmaceutical, and chemical industries.

Manufacturing Industry

In the manufacturing sector, Hazard and Operability analysis is vital for identifying potential hazards during the production process. By systematically examining each step and component, manufacturers can prevent accidents, ensure worker safety, and maintain product quality. Hazard and Operability analysis helps identify potential process deviations, equipment failures, and operational risks that could lead to costly downtime and potential harm to personnel.

Oil and Gas Industry

The oil and gas sector involves intricate processes that require diligent safety measures. Hazard and Operability analysis allows companies to assess the risks associated with exploration, production, transportation, and refining activities. By conducting thorough HAZOP studies, potential threats such as leaks, equipment malfunctions, and environmental hazards can be identified and mitigated effectively.

RELATED: HAZOP in Oil and Gas Industry: How to Prepare, Conduct, and Improve Safety in Malaysia

Pharmaceutical Industry

Pharmaceutical manufacturing introduces unique challenges due to the complexity of chemical processes and stringent regulatory requirements. Hazard and Operability analysis in the pharmaceutical industry helps identify and control risks associated with drug production, ensuring product safety, efficacy, and compliance. This critical process safety methodology reduces the chances of errors, cross-contamination, and deviations from critical process parameters.

Chemical Industry

The chemical industry is particularly prone to hazardous incidents due to the nature of its operations. Hazard and Operability analysis is crucial for identifying potential chemical reactions, process deviations, and equipment failures that can lead to fire, explosion, or release of toxic substances. By conducting HAZOP studies, chemical manufacturers can implement necessary safeguards to prevent accidents and protect the environment.

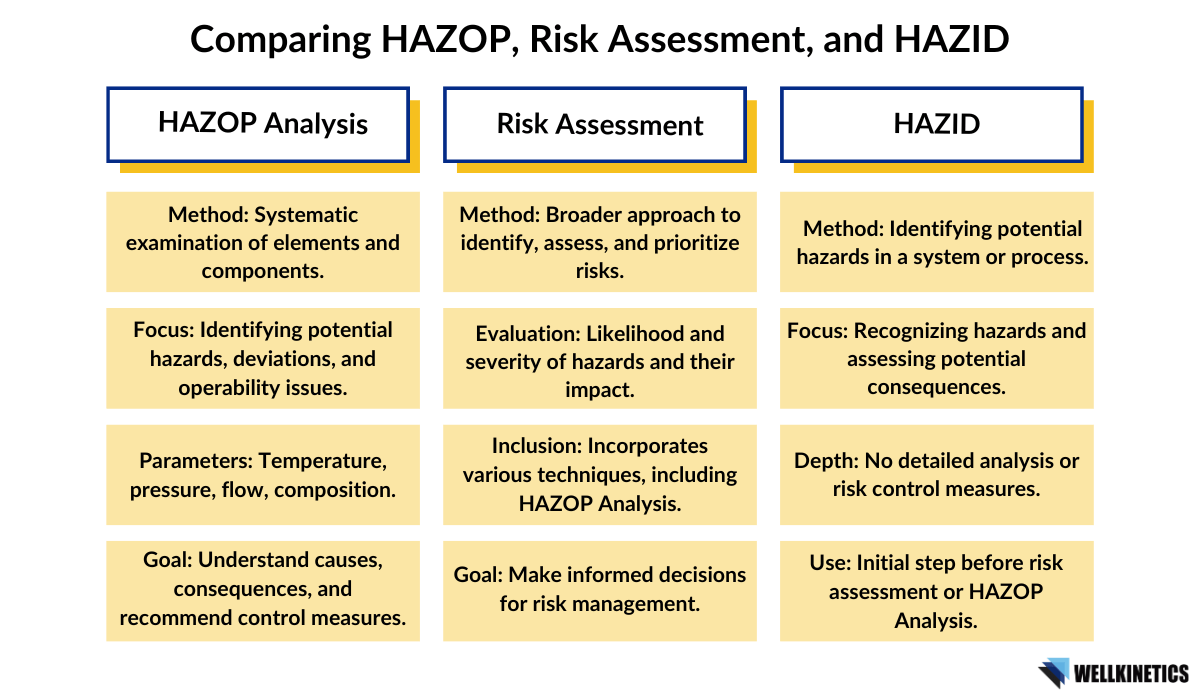

Differentiating HAZOP, Risk Assessment, and HAZID

When it comes to managing risks and ensuring safety, various methodologies can be employed, including the HAZOP analysis process, which is crucial for identifying and mitigating risks. Here, we will explore the differences between hazard and operability (HAZOP) analysis, risk assessment, and hazard identification (HAZID), highlighting their unique approaches to ensuring workplace safety.

HAZOP Analysis

HAZOP Analysis which stands for Hazard and Operability Analysis (Hazard and Operability Study), is a systematic and structured process aimed at identifying potential hazards, deviations, and operability issues within a system or process. This Hazard and Operability methodology involves a multidisciplinary team that examines each element and component, considering different parameters such as temperature, pressure, flow, and composition. The main objective of Hazard and Operability analysis is to understand the causes and consequences of deviations from the intended operation and recommend appropriate control measures.

Risk Assessment

Risk assessment, on the other hand, is a broader approach used to identify, assess, and prioritize risks in a systematic manner. It involves evaluating both the likelihood and severity of potential hazards and their impact on people, the environment, and assets. Risk assessment incorporates various methodologies and techniques, including the HAZOP technique, to gather information and make informed decisions about risk management.

HAZID

Hazard identification (HAZID) is a process that focuses on identifying potential hazards in a system or process. It aims to recognize hazards and assess their potential consequences without going into detailed analysis or suggesting risk control measures. HAZID is often used as an initial step before conducting a more comprehensive risk assessment or HAZOP analysis.

While Hazard and Operability analysis, risk assessment, and HAZID share the common goal of identifying and mitigating risks, they differ in terms of approach and scope. The Hazard and Operability analysis process is a targeted evaluation of specific components and deviations, while risk assessment provides a comprehensive overview of risks. HAZID serves as an essential preliminary step in the risk management process, paving the way for more detailed evaluations.

Remember that each approach has its strengths and limitations, and the choice of methodology depends on the specific needs and requirements of the system or process under evaluation.

RELATED: HAZOP vs. HAZID: Key Differences, Applications, and When to Use Each in Malaysia

Not Sure Which Approach to Use?

Let Wellkinetics help you choose the best safety analysis method for your needs.

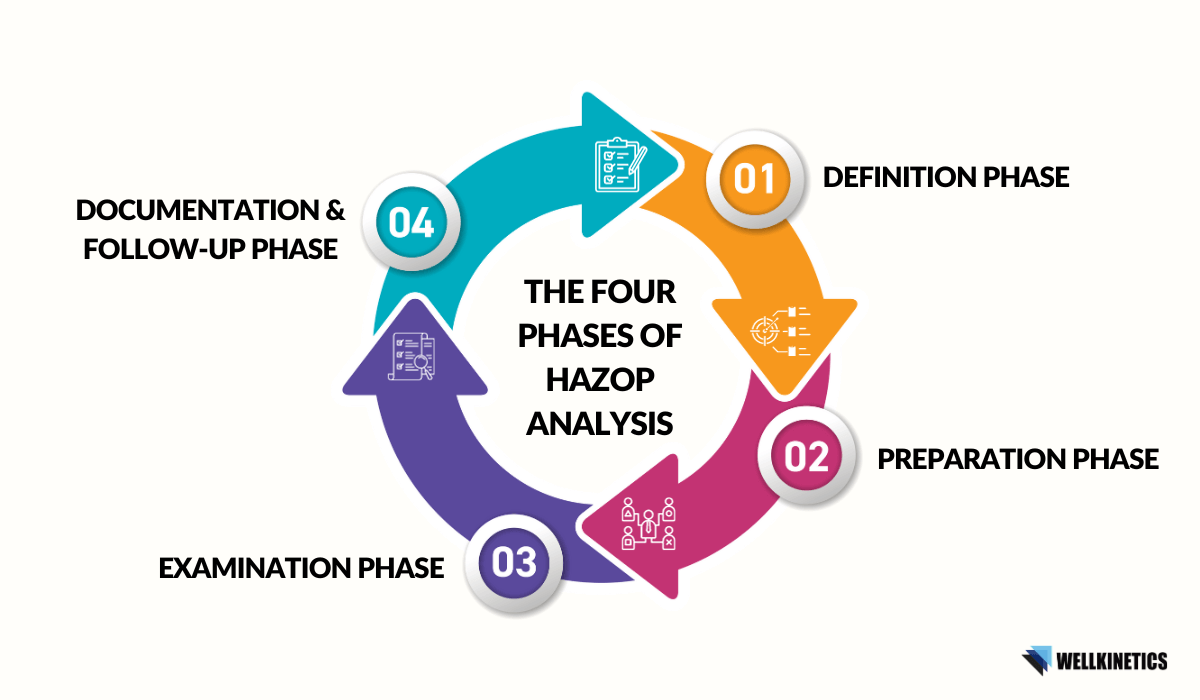

The Four Phases of HAZOP Analysis

HAZOP analysis follows a structured approach that consists of four distinct phases: the definition phase, preparation phase, examination phase, and documentation and follow-up phase. Let’s explore each of these phases in detail.

1. Definition Phase

In the definition phase of Hazard and Operability analysis, the scope and objectives of the study are clearly defined. The HAZOP team establishes the boundaries of the analysis by identifying the systems, processes, or procedures that will be evaluated. It is crucial to have a thorough understanding of the system under study to ensure accurate and comprehensive hazard identification.

2. Preparation Phase

During the preparation phase, the Hazard and Operability team is assembled, comprising multidisciplinary experts who possess deep knowledge and experience in relevant fields. This diverse team helps bring in different perspectives and expertise to comprehensively analyze the system.

The team identifies and documents the relevant process parameters, such as temperature, pressure, flow rate, and composition, that will be examined during the analysis. These parameters serve as the basis for evaluating potential hazards and deviations.

3. Examination Phase

The examination phase is the core of Hazard and Operability analysis, where the team systematically reviews the process parameters and identifies potential deviations that may lead to hazardous situations. They use a structured approach, guided by guidewords such as “more,” “less,” “reverse,” and “other than,” to systematically brainstorm deviations.

Through a series of brainstorming sessions, the team investigates each process parameter and applies the guidewords to provoke thinking around potential hazards. This process helps identify potential causes, consequences, and safeguards associated with each deviation.

4. Documentation and Follow-up Phase

In the final phase, the findings from the examination phase are documented in a Hazard and Operability report. The report includes a comprehensive list of identified hazards, associated consequences, and recommendations for mitigating risks.

The HAZOP team ensures that the report is thorough and well-documented, capturing all the necessary information. It also outlines the follow-up actions, including implementing proposed safeguards, conducting further studies if required, and monitoring the effectiveness of the implemented measures.

It is important to note that Hazard and Operability analysis is an ongoing process, and the documentation and follow-up phase play a critical role in continuous improvement and learning. Regular reviews and updates to the HAZOP study are necessary to adapt to changing systems, processes, and industry standards.

By following these four phases, organizations can effectively identify and mitigate potential hazards, ensuring a safer environment for workers and the surrounding community.

Let Us Help You Implement HAZOP Safely

Our HAZOP consultants can provide expert analysis, tailored to your organization’s needs.

How Wellkinetics Can Help?

Our team of knowledgeable professionals can guide you through the four phases of the Hazard and Operability analysis process, ensuring that each step is meticulously executed to achieve a successful outcome. By leveraging our understanding of the HAZOP methodology, we help businesses navigate the complexities of hazard identification and risk assessment effectively.

At Wellkinetics, we recognize the importance of effective risk assessment in the business domain. Our expertise lies in assisting organizations with the Hazard and Operability study process, enabling them to identify and mitigate potential safety hazards, thereby enhancing process safety and operability within their operations.

During the Definition Phase, we collaborate closely with your project team to define the scope and objectives of the analysis. By clearly outlining the boundaries and limits of the analysis, we ensure that all relevant areas are covered, preventing any potential hazards or operability issues from being overlooked in the process design, unless stated by client otherwise.

In the Preparation Phase, we gather all the necessary information and resources for the analysis. This includes obtaining essential documents such as process and instrumentation diagrams (P&IDs), operating procedures, and other relevant materials. Our meticulous approach guarantees that all necessary resources are available for a thorough examination of potential risks and hazards.

The Examination Phase is where our expertise truly shines. Our team systematically examines each identified node, applying suitable guidewords to explore deviations and identify potential hazards and operability issues. Through structured discussions and brainstorming sessions, we ensure that all risks are assessed and assigned a severity level for prioritizing mitigation measures effectively.

In the Documentation and Follow-up Phase, we compile all findings, recommendations, and actions identified during the analysis. A comprehensive HAZOP reporting document is prepared, detailing all the hazards, operability issues, and recommended control measures. Our team ensures that all relevant information is captured accurately, making it easier for you to implement necessary actions internally.

But our support doesn’t end with the analysis itself. We understand that implementation is key to achieving long-term success in process safety and operability. That’s why we help you establish a timeline for implementing the recommended control measures and assign responsibilities to the relevant individuals or departments. We believe that accountability is crucial in driving progress and ensuring that all mitigation measures are put into place.

At Wellkinetics, we take pride in our expertise, professionalism, and commitment to helping businesses achieve their risk assessment goals. With our guidance through the four phases of the Hazard and Operability study procedure, you can have peace of mind knowing that your organization’s process safety and operability are in capable hands, supported by effective risk management practices.

Why Wellkinetics?

Choosing the right partner for your HAZOP study process is crucial to ensure a successful outcome. Here’s why Wellkinetics is the ideal choice for your business:

1. Expertise in Business Risk Assessment: At Wellkinetics, we specialize in providing risk assessment solutions for businesses. We understand the unique challenges and requirements of the business domain and tailor our approach accordingly. With our deep knowledge and experience, we can help you identify and mitigate potential hazards to enhance process safety and operability effectively.

2. Implementation Support: We believe that the real value of the Hazard and Operability study lies in its implementation. That’s why we go beyond just providing analysis and recommendations. We help you establish a timeline for implementing the recommended control measures and assign responsibilities to ensure accountability.

3. Customized Solutions: At Wellkinetics, we recognize that every business is unique, with its own set of processes, operations, and challenges. That’s why we offer customized solutions tailored to your specific needs. Our team takes the time to understand your business and its requirements, allowing us to provide targeted recommendations and strategies for risk assessment and mitigation.

4. Continuous Support: We understand that process safety and operability are ongoing concerns for businesses. That’s why our support doesn’t end with the completion of the Hazard and Operability study. We are committed to providing continuous support, offering assistance and guidance whenever you need it. Our team is just a phone call or email away, ready to address any questions or concerns that may arise.

5. Industry Experience: With years of experience in the business domain, our team at Wellkinetics has worked with a wide range of industries, including manufacturing, oil and gas, pharmaceuticals, and more. This extensive industry experience allows us to bring a wealth of knowledge and insights to your Hazard and Operability study, ensuring that we can effectively address the specific challenges and requirements of your industry.

Contact us today to schedule a consultation and learn more about how Wellkinetics can assist your business in conducting a comprehensive Hazard and Operability study. Our team of experts is ready to collaborate with you and ensure that your organization is equipped with the necessary tools and knowledge to identify and mitigate potential hazards effectively.

When you choose Wellkinetics as your partner for your HAZOP study process, you can be confident that you are working with a trusted and reputable company. We have a proven track record of delivering successful outcomes for our clients, helping them enhance their process safety and operability.

Don’t leave the safety and operability of your business to chance. Partner with Wellkinetics today and secure the peace of mind that comes with having a dedicated team of experts by your side. Together, we can create a safer and more efficient operating environment for your business, ensuring its long-term success.

Learn more about our Process Safety Management Consulting Services.