In today’s fast-paced corporate environment, ensuring workplace safety and compliance is paramount. Enter Process Safety Management (PSM) – a comprehensive approach that safeguards employees and mitigates potential hazards. But what exactly is Process Safety Management, and how can it benefit your organization? Allow us to guide you through the essentials.

Imagine a workplace where employees feel safe, where operations run smoothly, and incidents are minimized. This ideal scenario can become a reality with Process Safety Management. By implementing PSM, you establish a framework that identifies, assesses, and controls potential hazards associated with highly hazardous chemicals.

In this article, we will provide an in-depth exploration of the elements and requirements of Process Safety Management. From understanding the purpose of the 20-element Process Safety Management framework by the Center for Chemical Process Safety (CCPS) to complying with regulatory guidelines, we will equip you with the knowledge to create a safe and compliant work environment.

Read on as we dive into the critical components of Process Safety Management and discover how it can revolutionize your workplace, promoting a culture of safety and well-being for your workforce.

- Understanding Process Safety Management (PSM)

- The Core Components of Process Safety Management (PSM)

- Ensuring Compliance with Process Safety Management (PSM)

- Advantages of Process Safety Management (PSM)

- Implementing Process Safety Management (PSM): A Step-by-Step Guide

- Process Safety Management (PSM) Consulting Services

- Why Choose Wellkinetics

Understanding Process Safety Management (PSM)

Process Safety Management (PSM) is a key system designed to prevent accidents in places that handle dangerous chemicals. Its main job is to make sure safety measures are in place to protect workers, nearby communities, and the environment. PSM is all about minimizing risks when dealing with hazardous substances during manufacturing, handling, and processing.

Why PSM is Important

The main aim of Process Safety Management (PSM) is to avoid major accidents, like fires or toxic releases, that could cause serious harm. It sets up clear rules and steps to control dangers from dangerous chemicals. By using PSM, companies can identify risks and put measures in place to keep everyone safe at work.

Where PSM is Applied

Process Safety Management (PSM) is crucial for industries that work with risky chemicals, such as refineries, chemical plants, drug manufacturers, and food processors. It covers everything from designing and building facilities to their day-to-day operations, ensuring that employees, contractors, and the public stay safe.

Want to Implement a Robust Process Safety Management?

Start with expert advice on how to build a strong Process Safety Management framework for your organization.

The Core Components of Process Safety Management (PSM)

Process Safety Management (PSM) is a thorough approach to handling the risks linked with highly hazardous chemicals and preventing workplace accidents. It involves implementing various strategies, protocols, and systems to ensure the safety of personnel, environmental protection, and the integrity of facilities and equipment.

The 20 Vital Elements of Process Safety Management (PSM) by CCPS (Center for Chemical Process Safety)

To prevent accidents and uphold a secure work environment, organizations need to address these 20 key elements of Process Safety Management (PSM):

1. Process Safety Culture

Cultivate a strong process safety culture across all levels of the organization, where safety is prioritized, and employees are actively engaged in identifying and mitigating risks.

2. Compliance with Standards

Ensure strict adherence to relevant industry standards and regulations to maintain operational safety and mitigate risks associated with non-compliance.

3. Process Safety Competency

Develop and maintain process safety expertise throughout the organization, ensuring all personnel have the knowledge and skills necessary to recognize and address safety challenges.

4. Workforce Involvement

Engage the workforce in safety initiatives, empowering them to contribute to hazard identification, risk assessment, and the implementation of safety measures.

5. Stakeholder Outreach

Foster communication and collaboration with stakeholders, including regulatory bodies, contractors, and community members, to align safety goals and expectations.

6. Process Knowledge Management

Effectively manage and document process knowledge to ensure that critical safety information is accessible and shared across teams for informed decision-making.

7. Hazard Identification & Risk Analysis

Systematically identify potential hazards and assess associated risks, using tools like hazard analysis and risk assessments to develop targeted risk reduction strategies.

8. Operating Procedures

Establish, review, and update comprehensive operating procedures that guide safe and efficient operations, ensuring consistency and reliability in process execution.

9. Safe Work Practices

Implement and enforce safe work practices to minimize risks during routine operations, maintenance, and emergency situations.

10. Asset Integrity & Reliability

Ensure the ongoing integrity and reliability of assets by establishing robust maintenance programs, regular inspections, and timely repairs to prevent equipment failures.

11. Contractor Management

Develop procedures for managing contractors, ensuring that external personnel comply with organizational safety standards and contribute to a safe working environment.

12. Training & Performance Assurance

Provide ongoing training and performance assessments to ensure that employees remain competent and aware of their roles in maintaining process safety.

13. Management of Change

Establish processes to manage changes in equipment, processes, or personnel, ensuring that modifications do not introduce new hazards or safety risks.

14. Operational Readiness

Ensure that all processes, equipment, and personnel are fully prepared for operation by conducting regular checks and reviews to confirm readiness.

15. Conduct of Operations

Implement a systematic approach to daily operations that fosters consistency, discipline, and adherence to safety protocols, minimizing deviations that could lead to incidents.

16. Emergency Management

Develop and test emergency response plans to prepare for potential incidents, ensuring a swift and effective response to mitigate consequences.

17. Incident Investigation

Establish a rigorous incident investigation process to identify root causes, learn from past events, and implement corrective actions to prevent recurrence.

18. Measurement & Metrics

Use key performance indicators (KPIs) and other metrics to measure the effectiveness of the PSM program, providing data to drive continuous improvement.

19. Auditing

Conduct regular audits to assess compliance with PSM standards and identify opportunities for improvement, ensuring that the system remains effective and relevant.

20. Management Review & Continuous Improvement

Regularly review the PSM program at the management level, incorporating feedback, lessons learned, and new safety insights to ensure continuous improvement and adaptation to evolving risks.

Following these PSM elements empowers organizations to identify, assess, and control potential hazards, ensuring employee safety and asset protection. Addressing each element comprehensively significantly reduces the risk of accidents and promotes a secure work environment.

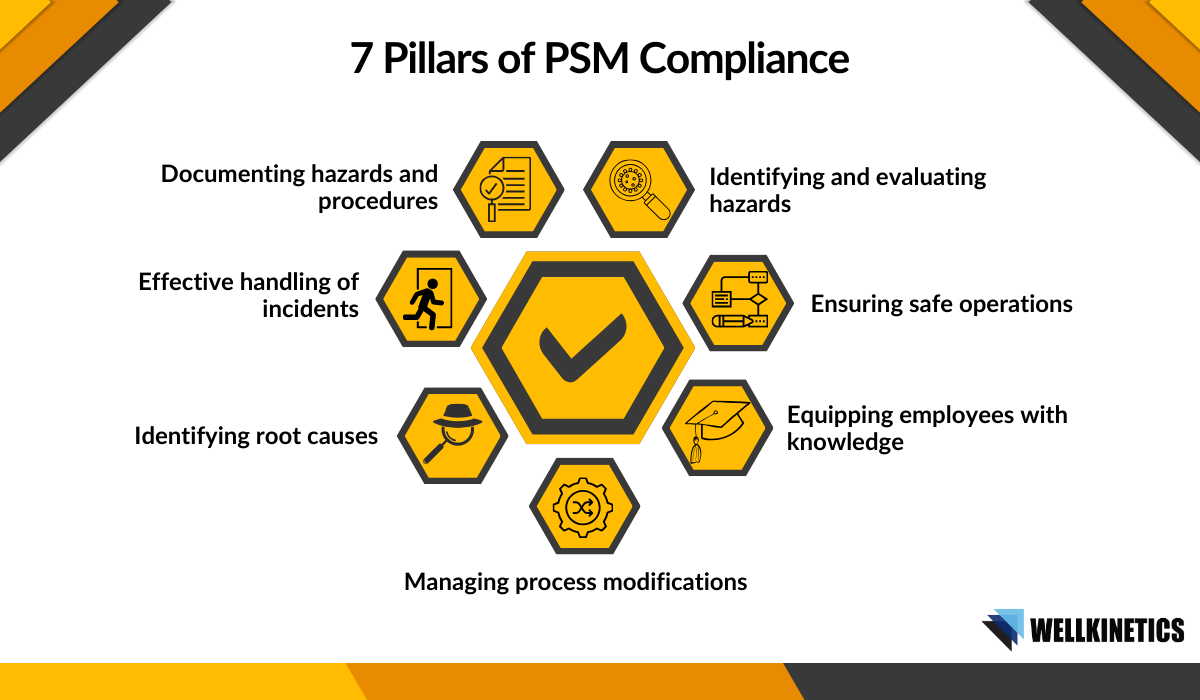

Ensuring Compliance with Process Safety Management (PSM)

Process Safety Management (PSM) stands as a vital framework that organizations must follow to effectively handle and reduce risks linked with highly hazardous chemicals. Adhering to PSM requirements is crucial for upholding workplace safety and preventing catastrophic incidents.

Why Compliance Matters

Complying with PSM standards goes beyond meeting legal obligations; it is a cornerstone in safeguarding the well-being of employees and protecting the local community. By sticking to PSM requirements, organizations can spot potential hazards, put necessary controls in place, and establish strong safety protocols.

Key Requirements for Implementation

Implementing PSM involves addressing several key requirements:

1. Process Safety Information (PSI) Management:

Maintain accurate and up-to-date documentation of process hazards, operating procedures, equipment specifications, and design or construction information. This ensures effective risk management.

2. Process Hazard Analysis (PHA):

Conduct thorough PHAs regularly to identify and evaluate potential hazards associated with chemical processes. Regular PHAs ensure comprehensive hazard identification and analysis.

3. Operating Procedures:

Establish clear and documented operating procedures to ensure safe and consistent operations. Provide employees with guidelines for working with hazardous chemicals.

4. Training and Competency:

Implement adequate training programs to equip employees with the knowledge and skills needed to safely handle hazardous chemicals and respond to emergencies. Regular refresher courses are essential.

5. Management of Change (MOC):

Set up rigorous procedures for managing changes to processes, equipment, personnel, and operating conditions that may impact safety. Proper evaluation and authorization minimize risks associated with process modifications.

6. Incident Investigation:

Thoroughly investigate incidents and near-misses to identify root causes and implement corrective actions. A robust incident investigation process helps mitigate risks.

7. Emergency Planning and Response:

Develop adequate emergency response plans, including evacuation procedures, communication protocols, and training. Regular drills ensure preparedness for handling incidents effectively.

By addressing these requirements, organizations can effectively implement PSM practices and maintain compliance with industry standards and regulatory obligations. This not only ensures a safer workplace but also demonstrates a commitment to responsible and ethical operations.

Struggling with Compliance? We Can Help.

Wellkinetics offers services to ensure your business meets the latest PSM regulatory requirements.

Advantages of Process Safety Management (PSM)

Process Safety Management (PSM) emerges as a critical force in ensuring workplace safety and compliance. Beyond preventing accidents and incidents, the implementation of PSM brings forth several significant benefits, contributing to a safer and more efficient working environment.

1. Improved Worker Safety:

PSM enhances the safety of employees by identifying and managing potential hazards, fostering a secure working environment. This proactive approach reduces workplace accidents, injuries, and illnesses, prioritizing the well-being of the workforce.

2. Reduced Incidents:

Implementing PSM helps organizations minimize incidents like fires, explosions, chemical releases, and other hazardous events. Adhering to PSM guidelines enables companies to identify and control potential risks, thereby lowering the likelihood of accidents and environmental damage.

3. Enhanced Operational Efficiency:

PSM implementation not only emphasizes safety but also elevates operational efficiency. Through improved process controls, equipment maintenance, and employee training, organizations optimize their operations. This results in increased productivity, reduced downtime, and improved overall performance.

4. Regulatory Compliance:

Complying with PSM standards ensures that organizations meet legal requirements set by workplace safety and health laws regulator and enforcer in Malaysia i.e. Department of Occupational Safety and Health (DOSH). PSM implementation allows companies to showcase their dedication to safety, mitigating potential legal issues and penalties.

5. Protection of Reputation:

A robust Process Safety Management system safeguards a company’s reputation by building trust among stakeholders – employees, customers, regulators, and the general public. Demonstrating commitment to safety and incident prevention enhances the organization’s image and credibility.

Implementing PSM not only aligns with legal obligations but also establishes a foundation for a positive workplace culture, operational efficiency, and a trustworthy reputation. These benefits collectively contribute to the long-term success and sustainability of the organization.

Implementing Process Safety Management (PSM): A Step-by-Step Guide

Implementing Process Safety Management (PSM) is paramount for organizations to ensure employee safety and adhere to relevant standards. By following practical steps and guidance, organizations can establish and maintain an effective PSM program. Here are the key steps:

1. Establish Management Commitment and Leadership:

- Demonstrate top management’s strong commitment to safety.

- Allocate necessary resources for PSM and appoint a dedicated coordinator or team for oversight and accountability.

2. Identify and Assess Process Hazards:

- Conduct a thorough process hazard analysis (PHA) using methods like What-If Analysis, HAZOP, or Fault Tree Analysis.

- Evaluate potential hazards associated with each process comprehensively.

3. Develop and Implement Operating Procedures:

- Create clear and concise operating procedures outlining safe practices for each process.

- Ensure all employees are trained on and have access to these procedures.

4. Provide Training and Education:

- Educate employees on PSM importance and their roles in maintaining a safe workplace.

- Conduct regular training sessions to enhance understanding of process safety and hazard control measures.

5. Establish Maintenance and Inspection Programs:

- Develop preventive maintenance programs for equipment reliability and to minimize potential process failures.

- Regularly inspect and audit equipment and facilities to identify and address safety concerns.

6. Emergency Planning and Response:

- Develop comprehensive emergency response plans outlining procedures for unexpected incidents.

- Conduct drills to test the effectiveness of plans and train employees on their roles during emergencies.

7. Contractor Management:

- Establish clear guidelines for contractors, ensuring adherence to PSM requirements.

- Provide appropriate training and supervision for contractors working on-site.

8. Continuous Improvement and Auditing:

- Regularly review the implemented PSM program through internal audits and inspections.

- Collect and analyze safety performance data, identifying areas for improvement and implementing corrective actions.

Implementing Process Safety Management requires a systematic approach and engagement from all organizational levels. By following these steps and consistently reviewing and enhancing the program, organizations can create a workplace prioritizing safety and protecting their employees.

Process Safety Management (PSM) Consulting Services

Seeking professional assistance from safety consultants is crucial for accurate implementation and compliance with Process Safety Management (PSM) standards. These consultants possess the knowledge and expertise to guide organizations in effectively establishing and maintaining a robust PSM program. Here’s why leveraging Process Safety Management consulting services can greatly benefit your organization:

1. Expert Guidance and Support

PSM consultants have years of experience and in-depth knowledge of the intricacies of process safety. They can provide expert guidance on interpreting regulations, implementing best practices, and identifying potential hazards. Their support ensures that your organization stays up-to-date with the latest industry standards and effectively addresses safety concerns.

2. Tailored Solutions

Every organization has unique processes and requirements. PSM consultants work closely with your team to assess your specific needs and develop tailored solutions that align with your operations. They conduct thorough audits, risk assessments, and process hazard analyses to identify vulnerabilities and recommend appropriate control measures.

3. Compliance with Regulatory Standards

Compliance with PSM regulations is essential to ensure a safe work environment and avoid penalties. PSM consultants assist in evaluating your organization’s compliance level, identifying gaps, and implementing corrective actions. Their expertise in regulatory requirements helps streamline processes and ensure adherence to all necessary standards.

4. Training and Education

PSM consultants provide comprehensive training programs tailored to the needs of your organization. They educate your staff on critical safety protocols, hazard recognition, and emergency response. By enhancing employee knowledge and skills, PSM consultants contribute to a safety-conscious culture within your organization.

5. Continuous Improvement

Process safety management is an ongoing endeavor. PSM consultants help you establish effective monitoring and evaluation systems, enabling continuous improvement. They conduct regular audits and inspections to identify areas for enhancement and ensure that your PSM program is constantly evolving to address emerging challenges.

Partnering with reputable PSM consulting services ensures that your organization has access to specialized expertise, tailored solutions, compliance assurance, and continuous improvement. By proactively addressing safety concerns and implementing industry best practices, you can maintain a safe and efficient work environment.

Facing Challenges in PSM Implementation?

We specialize in overcoming PSM implementation challenges with proven strategies.

Why Choose Wellkinetics

At Wellkinetics, we recognize the critical importance of PSM, and our comprehensive solutions are designed to empower your organization to implement and maintain a robust PSM program. From hazard identification to clear operating procedures and regular audits, our expert insights and support will elevate your safety standards to unprecedented levels.

Take the first step towards a safer and more prosperous future. Contact us today to embark on a transformative journey with Wellkinetics and unlock the remarkable benefits of Process Safety Management for your organization. Your safety matters, and together, we can create a secure and thriving workplace that ensures your organization’s long-term success. Trust Wellkinetics to be your partner in building a safer tomorrow.